According to ISO 14917 thermal spraying is a process in which surfacing materials are heated to the plastic or molten state, inside or outside of the spraying gun/torch, and then propelled onto a prepared surface. Since the 2017 version of this standard, laser cladding and plasma transferred arc welding (PTA) were included in the group of thermal spray processes as special surfacing processes by welding.

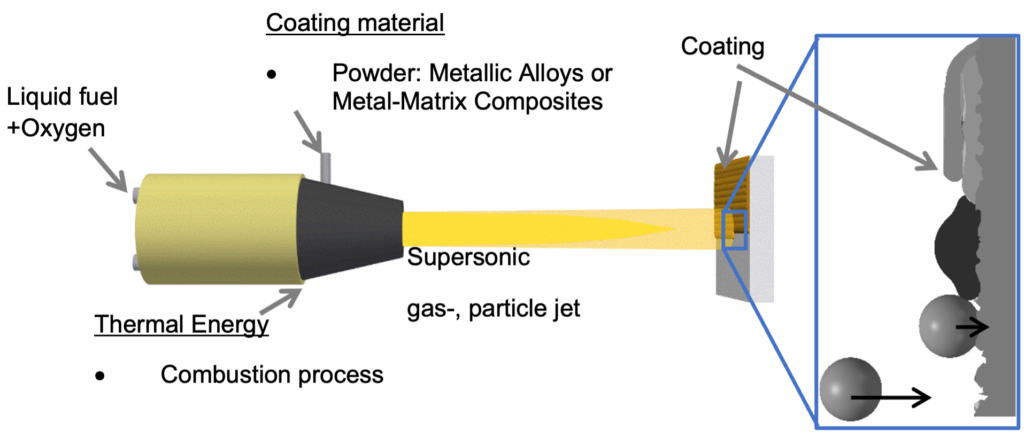

High Velocity Oxy Fuel (HVOF)

The HVOF process sprays semi-molten droplets of coating material at extremely high velocities (up to 1000 m/s), resulting in coated surfaces of the highest possible quality and performance to improve durability, resistance to corrosion, or both.

HVOF coatings can range from a few microns to several millimetres thick, are very dense, very well bonded, and free of the oxides and tensile stresses typically found in coatings provided by other thermal spray processes. Consequently, HVOF coatings perform better in service.

A range of metal substrates, such as tungsten carbides, stainless steel, nickel, bronze, aluminiumetc, are suitable for HVOF coating.

HVOF wear resistant surfaces are finished by grinding, polishing or super-finishing using diamond tools and typically provide more than four (4) times the wear resistance of chrome plating, through-hardening and other hard facing techniques.

HVOF coatings are increasingly being used around the world as more environmentally friendly and superior performing alternatives to chrome plating.

HVAF is a sub form of HVOF using Air instead of Oxygen for combustion.

Wire Arc Spraying

Invented in the early 20th century, Wire Arc Spraying uses a simple, low power arc drawn between two electrically charged wires to deliver the fastest coating rates of any technology.

Wire arc spray equipment resembles GMAW (MIG) welding equipment, in the power source and wire feeding units. The arc is ignited between the 2 wire tips where the wire material is melted. A gas stream, usually compressed air, takes the molten material and propels it towards the surface of the substrate material where the coating is formed.

Wire arc spray devices are thermally efficient and, because there is no flame or plasma, little heat is transferred to the part being coated. This process is most suited to applications requiring metallic, relatively heavy coatings where absolute coating quality (density, oxide content, etc) is not as important as coating cost and rate of deposition.

Plasma Spraying (APS)

Plasma spraying is a very versatile process, spraying all materials that are considered sprayable, from Aluminium to Zirconia.

In plasma spray devices, an arc is formed in between two electrodes in a plasma forming gas, which usually consists of either argon/hydrogen or argon/helium. As the plasma gas is heated by the arc, it expands and is accelerated through a shaped nozzle, creating velocities up to MACH 2. Temperatures in the arc zone approach 36,000’F (20,000’K). Temperatures in the plasma jet are still 18,000’F (10,000’K) several centimetres from the exit of the nozzle.

Plasma spraying is commonly used to coat structural materials to provide protection against corrosion, erosion, wear and high temperatures. Due to the high thermal energy of the APS process, APS is frequently used to apply ceramic coatings for thermal or electrical insulation. The process can also be used as a repair medium to replace worn material and to change the thermal, electrical or tribological property of a surface.

Plasma Transferred Arc (PTA)

The plasma transferred arc (PTA) weld hard facing process produces high quality weld overlays with relatively low heat input and very low dilution of the substrate into the weld overlay. It is essentially a hybrid process containing elements of thermal spray (powder consumable melted in a continuous plasma heat source) and weld (the melting and formation of a metallurgical bond with the substrate). With the torch manipulation generally automated this process can achieve uniform overlays on complex parts. The PTA process is typically used to apply relatively thick (2-3 mm) wear and / or corrosion resistant cobalt and nickel alloys.

The major disadvantage of the PTA process, compared to superior LaserBond laser cladding and thermal spray, a slow deposition rate of approximately 2kg/h, whereas in laser cladding LaserBond achieves 12 kg/h and more.

Spray & Fuse Hard Facing

During spray & fuse hard facing a low-melting point nickel or cobalt alloy is sprayed and subsequently fused onto a substrate. The fusing process can occur in a furnace or with a flame.

Spray and fuse produces dense wear resistant coatings of between 0.5 and 1.5 mm with good corrosion resistance. As a result of the fusing, the bonding between coating and substrate is metallurgical and therefore tolerant to impact damage. The major disadvantage of this process, compared to the superior

LaserBond laser cladding, is the coatings hardness and thickness is limited, and due to the high temperature, there are limitations on suitable substrate materials.

Polymer Coatings

LaserBond is now, through the purchase of our Victorian facilities, a licensee of the PCI range of traction and release coatings developed by Plasma Coatings International. These coatings combine a thermal spray bond coat with a polymer topcoat resulting in composite coatings with exceptional wear resistance, durability, and traction and release. These coatings are hydrophobic and resist microbial and fungal attack. These coatings systems are US Food and Drug Administration approved for direct food contact services.