Laser Cladding is the process of adding a metallic alloy to a new component to protect it against wear, corrosion or abrasion or to refurbish a worn component.

Laser Cladding is nowadays also referred to as Laser Metal Deposition (LMD), Direct Laser Deposition (DLD), Direct Energy Deposition (DED) or Direct Metal Deposition (DMD) in accordance with the international standard for Additive Manufacturing ISO/ASTM 52900. Some of these terms to some extent refer to the build-up of entire parts using Laser Cladding, nevertheless, they in principle are equivalent to the LaserBond’s Laser Cladding process developed in 2001.

First developed in the 1990s, Laser Cladding offered a better coating quality than the contemporary surface engineering techniques – a quality that would deliver even longer component life.

LaserBond commissioned the first Laser Cladding system in 2001 to further broaden our surface engineering capabilities and provide customers with access to coatings and overlays with a full metallurgical bond. LaserBond was the first company to use Laser Cladding as a surface engineering process commercially in the southern hemisphere, and one of the first worldwide.

Our early R&D was directed at integrating multi-axis robotics and breakthrough metallurgies (work that set us apart from our peer) and we have built on that framework to continue expanding our Laser Cladding capabilities and adding more powerful, more capable Laser Cladding systems into our workshops.

LaserBond®

Laser Cladding Parameters

Our Laser Cladding capabilities are continually expanding as is the range of materials we can clad. Our weight parameter ranges from a few grams up to 25t; diameters from 5mm up to 2000mm, and lengths up to 6 metres.

In line with goal of delivering innovative services and products we are constantly researching advanced surface engineering technologies that will expand our capabilities into applications previously considered unsuitable or uneconomic.

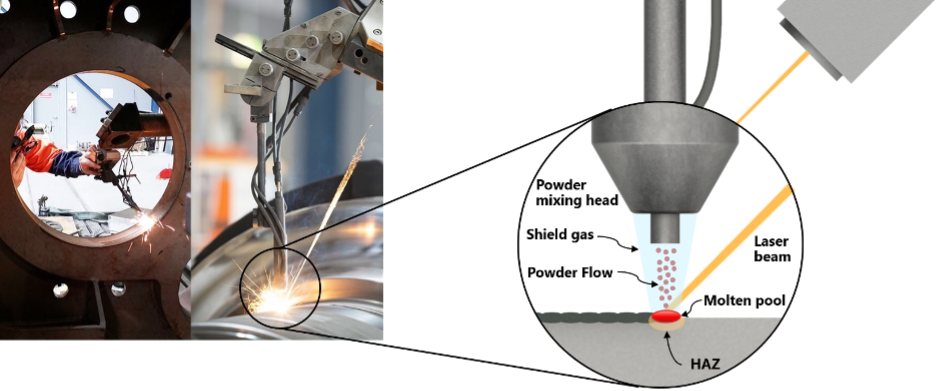

Diagram showing the Laser head.

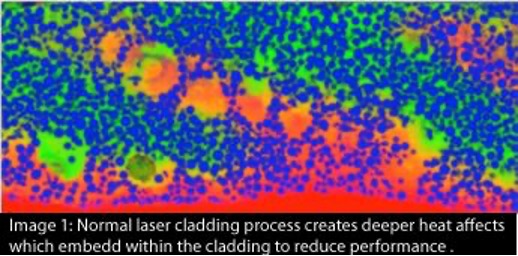

Image 1: Normal ‘laser cladding’ methods are limited totungstencarbide(shown blue)concentrations of about 60%.

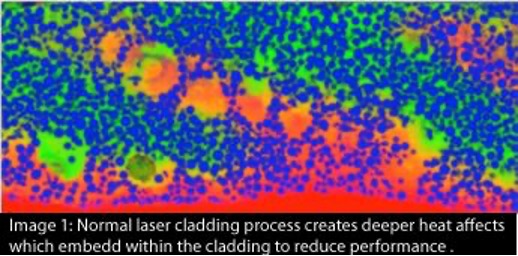

Image 2: Contrasting this is LaserBond’s new method, which contains higher concentrations of protective carbide, smaller particles and dramatically reduced dilution. Also there is almost no heat affected zone, which ensures structural integrity and dimensions of the substrate and ensures no breakdown or reduced performance of the carbide component.

Unique LaserBond Deposition Process

The R&D team have developed an advanced Additive Manufacturing method to deliver a major improvement in the laser deposition of composite materials for wear applications.

It has resulted in a number of related and international patents, recognition of the global application of this new technology.

Working with scientists at the Australian Synchrotron the outcomes are illustrated by way of some advanced imaging obtained using the Scanning X-ray Fluorescence Beamline Microscopy which enables particular submicron content to be scanned, identified and imaged. It provided unprecedented visual proof LaserBond’s new method was far superior to what had been used previously.

Images 1 & 2 shows the technical benefits of increased and more evenly distributed concentrations of protective carbides, minimal effects to carbide particles and dramatically reduced dilution.

Wear-life performance in particularly erosive and abrasive applications is affected by dilution of base material (red coloured), porosity and areas of low concentration of carbides (multicoloured and green).

Commercial Benefits

The new LaserBond® laser cladding method offers further improvements to wear-life, thinner coatings and better economics for customers.

Contact Us

For our technical expertise to advise on how this new laser cladding process can be applied in your industry