Prevenir o desgaste onde ele começa... com o revestimento certo

In general, the processes that lead to, and ultimately identify, component failure occur on the surface – usually at a contact point, which can quickly become a wear point.

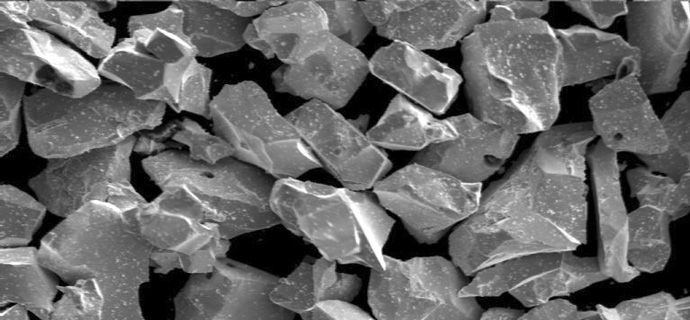

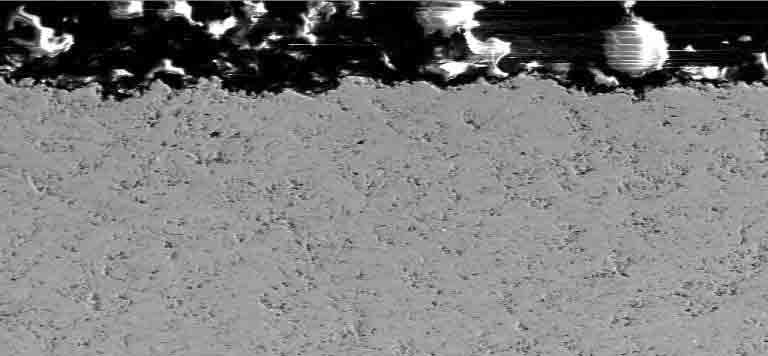

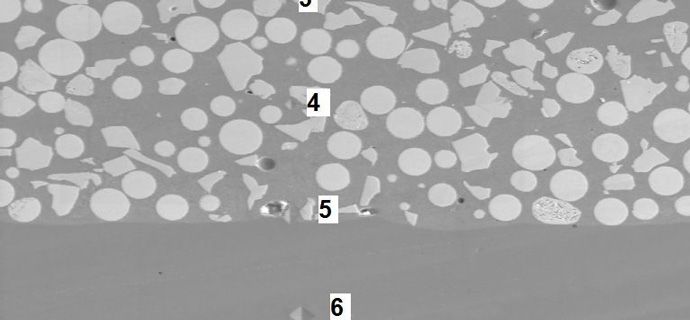

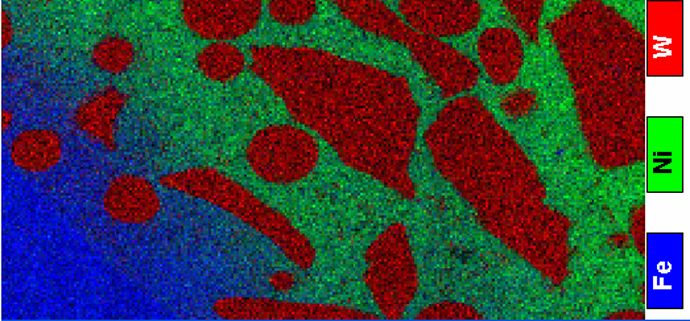

As an integral part of LaserBond’s surface engineering process, carefully selected functional coatings, which take account of substrate properties and component use, are applied to change the surface properties of the substrate to protect from mechanical erosion, corrosion and wear. These same coatings increase component performance and wear resistance.

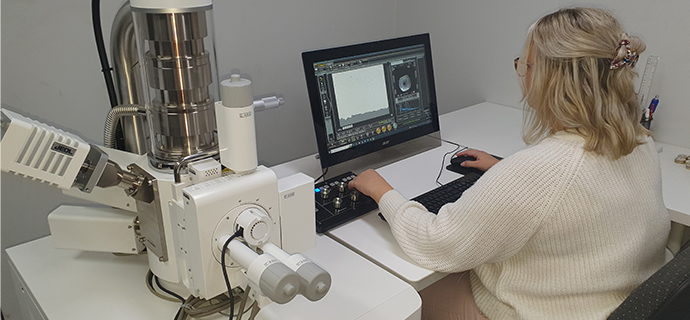

A complementary range of laboratory equipment and measurement devices, including optical microscopes and microhardness testing equipment, enables a range of spectrum and composition analysis and non-destructive testing. As an on-site facility, direct access to analysis and testing allows continual refinement of manufacturing and surface engineering techniques – optimising of the products and services we can provide our customers.

The laboratory also allows our Research and Development team and material scientists to research surface engineering applications and tailor solutions to specific wear problems – solutions including innovative techniques and applications, system and product design and exotic materials.