Static and mobile machinery and equipment

Graders. Excavators. Backhoes. Blades. Buckets. Cranes. Compressors. Specialised vehicles. Assets vital to business operations. Assets that are subject to wear, mechanical erosion and corrosion but must keep performing. To achieve profitability. Assets that take time to change-out. And that costs.

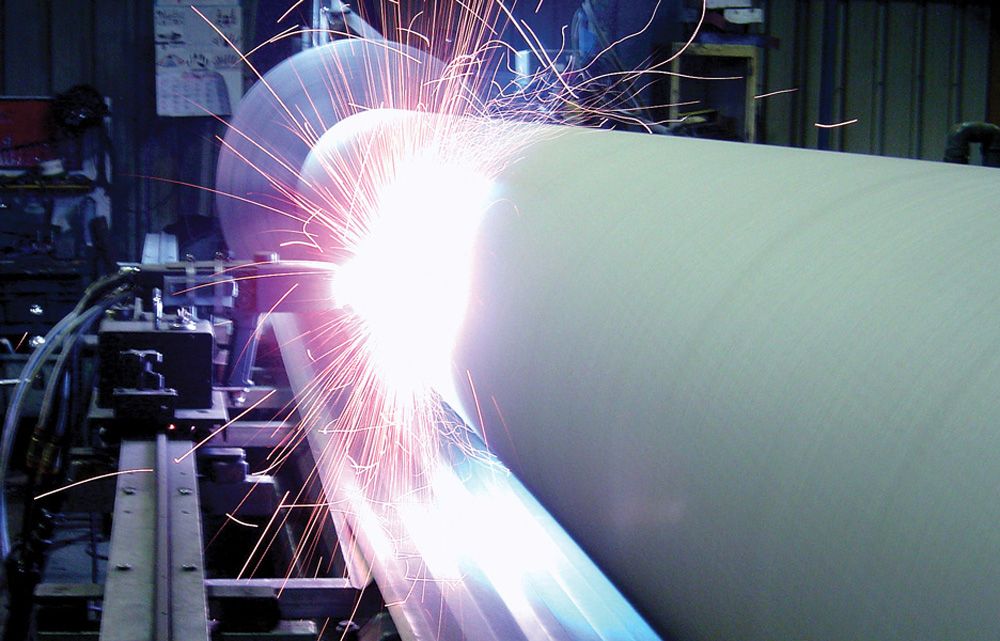

LaserBond surface-engineering technologies extend plant and machinery life, increase reliability and reduce unit operating and maintenance costs. They decrease the potential for breakdowns to production-vital components by improving resistance to wear and corrosion. They increase component performance.

We can also recover and remanufacture fatigued metal components and surface-engineer them for extended operational and service life in a range of challenging environments – at a fraction of the cost of replacement OEM parts.

Benefits:

Longer Operating Lifespan

Surface engineering is in our DNA. We surface engineer and metallurgically clad production parts and components subject to wear, corrosion and mechanical erosion. To give them a longer operating lifespan.

Improved Performance and Efficiency

When LaserBond surface engineered, production equipment and components work better. Overall performance is improved. Reliability is improved. Efficiency levels rise. Prodcution goes better – and can be more profitable.

Higher Availability; Lower Costs

Keeping equipment working and profitable is the goal. Breakdowns and breakages cost. LaserBond surface engineering extends operational life of production equipment. This means higher availability – reduces the chance of breakages – lower costs. Win win.

Estudos de caso

Our Stories… an enviable reputation built on solid performance.

Concrete slip forming machines allow the continuous in-situ pouring of

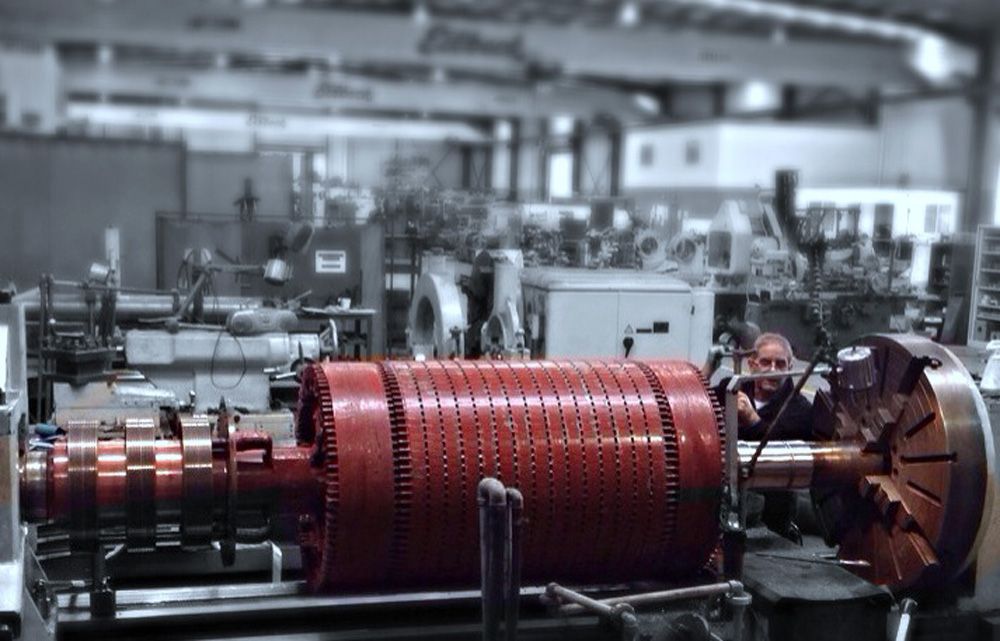

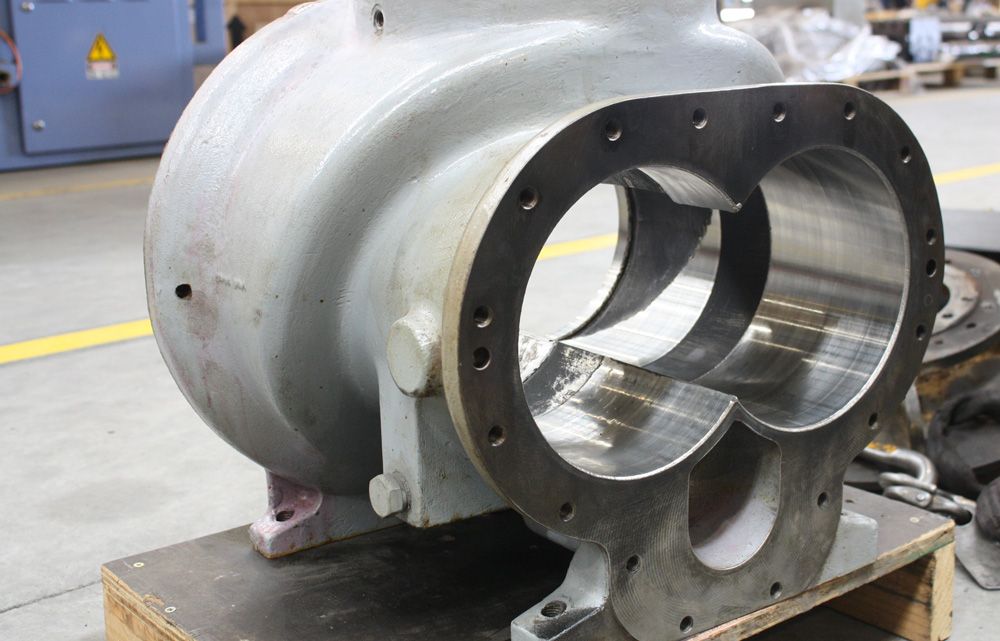

A rotary screw compressor is a type of gas compressor