Thermal Spraying … mechanically bonded high-performance surfaces

Thermal Spraying is a coating process which produces high-performance surfaces with absolutely no risk of distortion or metallurgical changes to the component. LaserBond has a range of coating processes to apply cost-effective metallic or non-metallic based coatings onto (usually) metallic substrates.

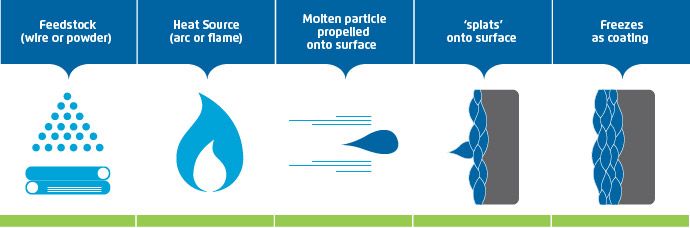

In these processes, the coating material is introduced to an extreme heat source in the form of wire or powder. The molten material is transferred to the component at a very high velocity where it mechanically bonds to the substrate. Our thermal spray booths are designed for both high volume production and short-run projects.

At LaserBond we use a number of thermal spray processes including

- High-Velocity Oxy-Fuel (HVOF) and High-Velocity Air-Fuel (HVAF)

- Plasma spraying (APS)

- Wire arc spraying

- Flame spraying

- Spray and Fuse

Benefits:

- No dilution or distortion of components

- Can be applied on many base materials, including cast iron and composites (CFC and GFC)

- Wide range of coatings available, including ceramics and cements

- Highest wear protection

- Corrosion protection

- Electrical insulation

- Thermal insulation

- Cost-effective life extension

Applications:

- Knife edges, blades and cutting tools

- Wear surfaces

- Part-to-part sliding abrasion sites

- Thermal Barrier Coatings (TBC) for turbomachinery

- Shafts, journals and sleeves