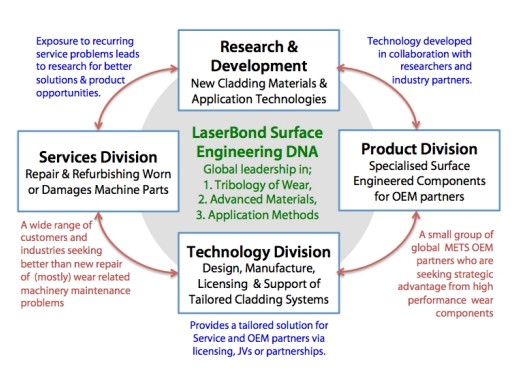

Surface engineering is in our DNA and fuels our passion for new surface engineering metallurgy, technologies and techniques that will extend wear lifespan and improve the performance of components and equipment. For many decades we’ve seen the aerospace and automotive industry advance rapidly with new materials, surface engineering and additive manufacturing processes; LaserBond is leading in the heavy industry and resources sector.

Our Research & Development team is backed by more than 30 years’ experience in industrial tribology, in particular on the impacts and effects of multi-modal wear in aggressive heavy industrial environments. LaserBond’s R&D work is directed towards expanding three surface engineering skill sets that are our core DNA at LaserBond:

- Tribology of Wear in Heavy Industrial – Aggressive Conditions: Working with University of South Australia: Future Industries Institute (UniSA:FII) and our CRCp collaboration we will develop a world class heavy industry wear laboratory. It’s being equipped with multiple standardised wear testing units, plus a custom rig that reflects problematic conditions found with drilling and processing of acidic, hard rock types with extremely high velocity particles (found in wet drilling and slurry pumps).

- Advanced Metallurgy & Cladding Materials – Powdered Metal: Using new metal powders, some with modified characteristics combined with more economical application technology, LaserBond material scientists are able to develop new cladding materials tailored to better understand wear mechanics. Our collaboration with UniSA:FII enables the team to analyse and characterise materials and bonding.

- Application Methodologies – Additive Manufacturing: LaserBond uses a suite of additive manufacturing technologies. Efficient high-power diode lasers and new thermal spray processes are leveraging the knowledge of materials. We are discovering new ways of applying cladding, with higher efficiency. By building our own machinery we have extended the applications that can now benefit from surface engineering.

The team investigates the reasons and effects of high wear and component failure, then finds solutions utilising our expertise in metallurgy and powder coating application technology. Embedding innovation into product and service development helps our customers increase resource efficiency, operate more safely, and reduce environment impact.

Continued Reinvestment in R&D

Throughout our history LaserBond has continuously reinvested in our R&D program, with R&D expenditure being a KPI of our business. With the growing acceptance of surface-engineered components for wear applications LaserBond has a collaboration agreement with UniSA: FII to pursue deeper science on both metallurgy and application methodologies.

The current target for direct R&D investment is 5% of sales revenue. Working with industry collaboration partners like University of South Australia and key customers, we also access government grants that provide a multiplier effect – they turn our $1 of R&D spend into $2 or $3, which accelerates or expands outcomes.

University of SA – Future Industries Institute signs LaserBond

Designing New Surface Coatings

LaserBond’s material scientists work with customers to develop a tailored solution for their specific surface engineering requirements.

A customer describes their components application and desired surface properties. We learn more about the environment the coating will be used in, and then design the properties required to withstand the environment.

LaserBond applies its extensive materials engineering expertise to design a coating and method solution to fulfil a component’s specific duty. We have access to a materials and alloy database of some 1 million variants.

Combining a well-engineered coating material and component design delivers longer life higher performance outcomes at the lowest cost.

units to handle high loading and high temperature (preheated) components that deliver precise relative movement control when integrated with the long reach robot head.

New proprietary control software integration and HMI has been developed to support the advancements. It incorporates secure connections that enable our licensees and technical support staff to provide analysis, parameter settings and training remotely.