LaserBond is a specialist surface engineering company founded in 1992.

LaserBond focuses on the development and application of materials, technologies and methodologies to increase operating performance and wear life of capital-intensive machinery components.

Within these industries, the wear of components can have a profound effect on the productivity and total cost of ownership of their capital equipment. As almost all components fail at the surface, due to material removal through abrasion, erosion, corrosion, cavitation, heat and impact, and any combinations of these wear mechanisms, tailored surface metallurgy will extend its life and enhance its performance.

Applications across many industries

LaserBond recognises that its technology has applications across many industries as more sectors accept that surface engineering technologies can deliver significant cost-effective improvements in productivity and/or lower total costs of ownership, mostly in resources and energy, agriculture, advanced manufacturing, defence and infrastructure construction.

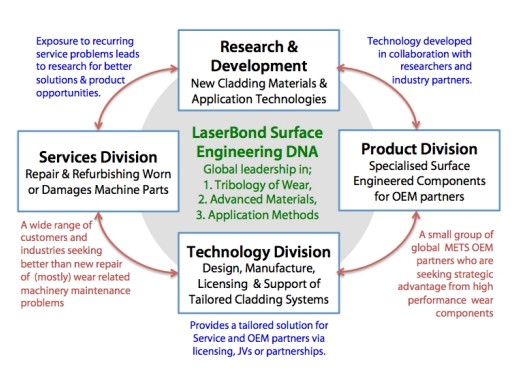

Our growth has been built on the pursuit of innovation and technology leadership in three surface engineering foundations:

- Tribology of wear and performance in heavy industrial components.

- Metallurgy and science of high-performance materials.

- Optimisation of a wide range of materials and application methodologies.

This is supported by marketing and sales focus that seeks opportunities offering productivity and sustainable gains by:

- Identifying components, equipment or applications that benefit from our technologies.

- Customer partners with established needs and markets.

Our customers are typically internationally recognised Original Equipment Manufacturers (OEMs) and capital-intensive heavy industries that endure high costs whenever their equipment is out of production for maintenance. These customers recognise LaserBond’s focus on workplace health & safety, quality assurance and the environment which is delivered through our certified PAS99 integrated management system.

Other very important areas our customers benefit from utilising our services is in the workplace health & safety and a positive contribution to the environment:

- WH&S benefits are often realised because the maintenance of equipment and replacement of worn parts is often carried out in potentially hazardous environments (e.g. on mine sites) and/or involves handling of difficult and heavy components. Many of our customers recognise that by reducing the frequency of required maintenance, the utilisation of LaserBond’s services significantly lowers the risk of injury to personnel.

- Environmental benefits arise from LaserBond’s ability to remanufacture and provide performance improvements to machine parts that would have typically been scrapped and replaced with new parts. The typical carbon footprint for a LaserBond remanufactured part is less than 1% of a new part, and with life improvements between 2 to 20 times of standard parts, a carbon footprint of much less than 1% is achieved.

LaserBond operates from facilities in New South Wales, Queensland, South Australia and Victoria.

Downloads

Board

Philip Suriano GAICD

CHAIRMAN/NON-EXECUTIVE

DIRECTOR, AUDIT, RISK,

NOMINATION AND REMUNERATION COMMITTEE

MEMBER

Ian Neal

NON-EXECUTIVE DIRECTOR AND AUDIT, RISK, NOMINATION & REMUNERATION COMMITTEE

MEMBER

Dagmar Parsons

NON-EXECUTIVE DIRECTOR AND AUDIT, RISK, NOMINATION & REMUNERATION COMMITTEE

MEMBER

Leadership Team

Michael Tyler

chief operating officer

Sales Team

Technology and Licensing

Our culture of innovation enables us to deploy innovative surface engineering technology that reduces maintenance costs, improves performance, and extends machinery life.