About Laser Cladding

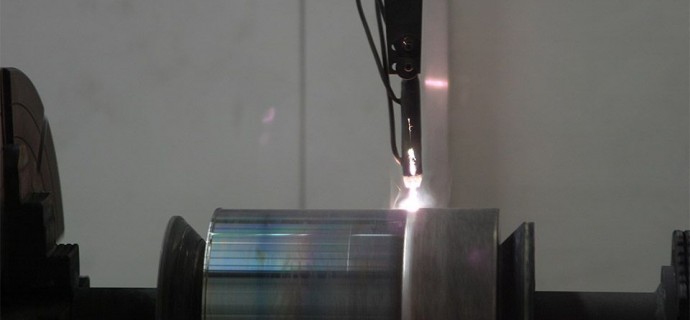

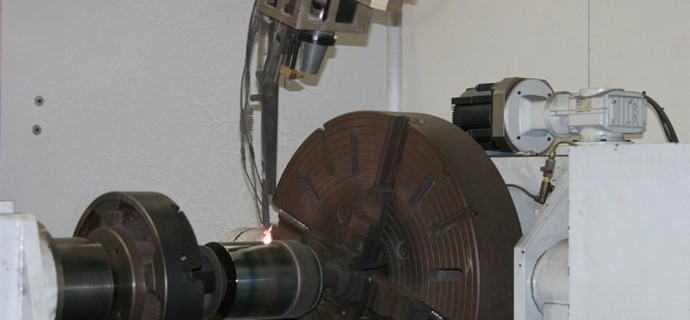

LaserBond® Laser Cladding, also called Laser Metal Deposition (LMD) is a high performance additive manufacturing procedure which utilises precisely-controlled energy from a high power laser to metallurgically-bond a surfacing material to a substrate to provide very high performance surfaces to new parts for extended operating life. With this precise control, a welded or metallurgical bond is achieved with minimal impacts and effects of heat on both the substrate and surface material.

LaserBond® Laser Cladding technologies offer a broad spectrum of industries confronting component and equipment wear issues significant opportunities to reduce maintenance costs and enhance operating performance.

Benefits:

- Limited dilution of coating for maximum purity and performance

- Precise, fully-fused deposit layer

- Short processing time minimises heat spread and impact

- Improves component wear performance

- Cost effective component life extension

- Can be used to reclaim worn or fatigued components

- Reduces maintenance and part replacement costs

- Suitable for sensitive components

Applications:

- High erosion from liquid or gas flows

- High impact conditions

- Part-to-part wear and abrasion